In the world of scientific research and experimentation, the quality of laboratory glassware can make the difference between accurate results and costly failures.

At Yash Instrument Company — one of the most trusted laboratory glassware manufacturers in India — we follow a strict 6-step quality assurance process to deliver products that meet ISO.

Our 6-Step Quality Assurance Journey

STEP 1 – Dedicated Quality Control Department

YASH INSTRUMENT COMPANY has one dedicated separate department for quality control where our team ensures that all the products meet international standards — from visual check to technical check.

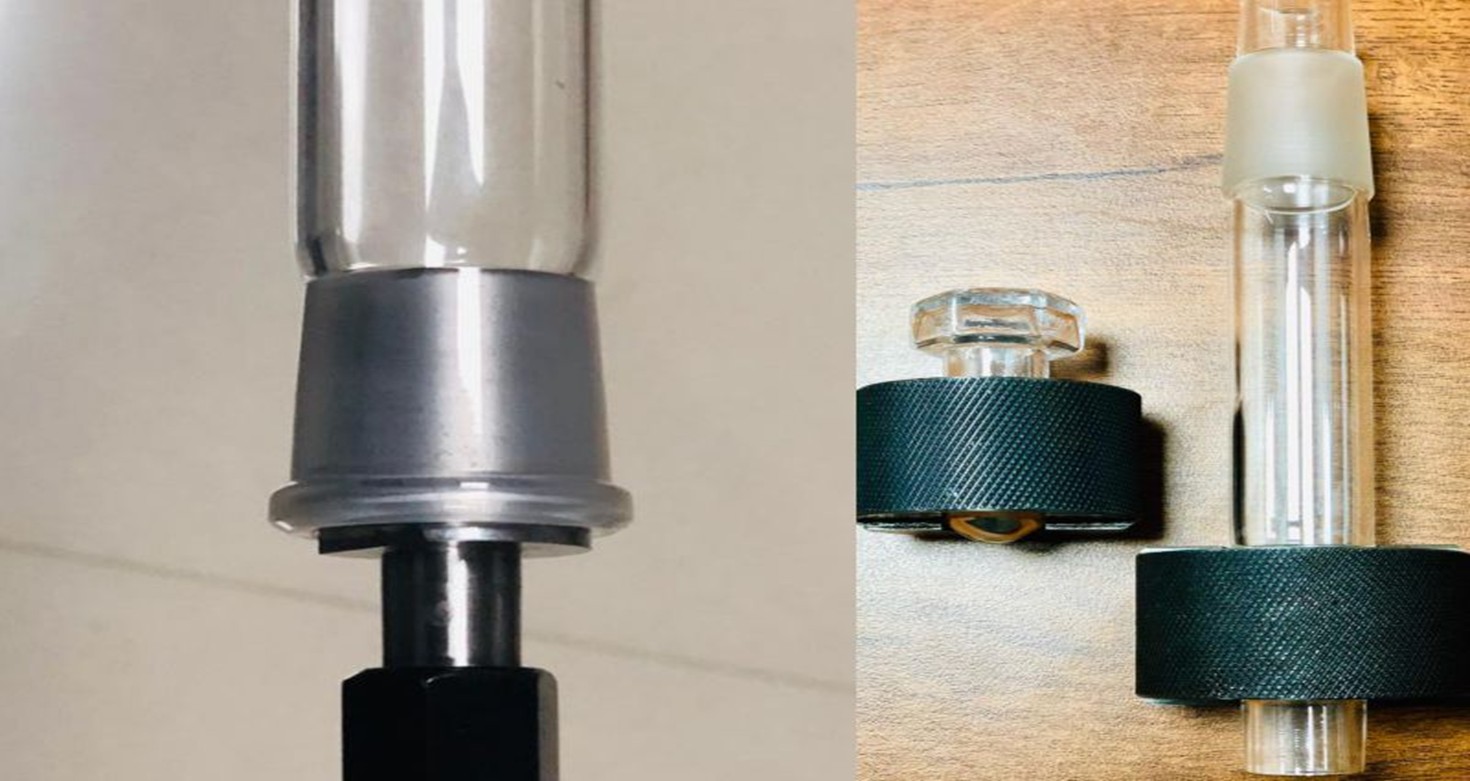

STEP 2 – Precision Joint Testing

All male (cones) & female (joints) are checked by highly precise tools to ensure joints are 100% leak-proof.

STEP 3 – Compliance with Global Standards

All dimensional checks are performed as per ISO • DIN • ASTM standards.

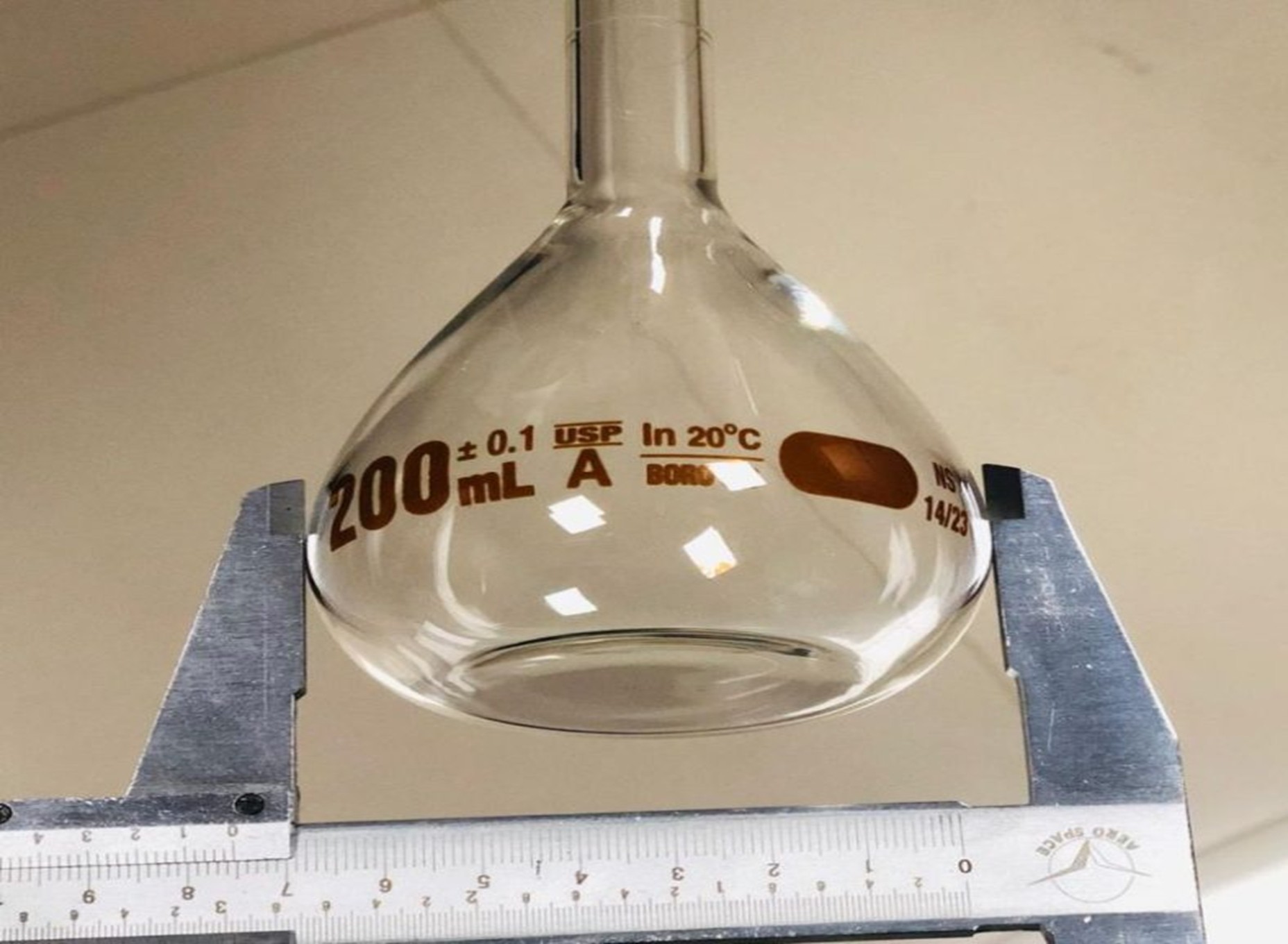

STEP 4 – Caliper-based Dimensional Verification

Every single piece produced goes through dimensional check with calibrated calipers — no exceptions.

STEP 5 – Uniform Wall Thickness

We ensure all products manufactured have uniform wall thickness according to international standards — crucial for thermal & mechanical strength.

STEP 6 – Professional Annealing Process

Equipped with modern annealing machines, we ensure every piece of laboratory glassware is properly annealed — eliminating internal stress for maximum durability.